Ecommerce businesses today face an increasing demand for faster, more accurate order fulfillment. Behind every smooth customer experience is a robust ecommerce warehouse system.

An ecommerce warehouse is more than just a storage space for products; it is the backbone of an efficient supply chain, ensuring timely delivery and customer satisfaction.

In this blog, you will learn how ecommerce warehouses function, the role of ecommerce fulfillment centres, best practices for inventory storage, and how innovative solutions can optimize shipping and order management.

By the end, WooCommerce store owners will also discover how tools like Discount Rules for WooCommerce – Pro can integrate seamlessly to maximize sales and promotions.

Boost your WooCommerce store sales and streamline promotions with Discount Rules for WooCommerce – Pro today!

Table of contents

- What is an Ecommerce Warehouse?

- Role of Ecommerce Fulfillment Centres

- Key Components of an Ecommerce Fulfillment Warehouse

- Ecommerce Storage and Inventory Management

- Warehousing and Order Fulfillment Process

- What Role Do Autonomous Mobile Robots Play in Warehouse Picking?

- Comparing Picking and Packing Processes Across Fulfillment Centers

- How Does Inventory Management Integrate With Order Processing?

- Types of Ecommerce Fulfillment

- Ecommerce Shipping and Delivery Operations

- How Technology Improves Ecommerce Warehouse Performance?

- How Ecommerce Warehouse Solutions Optimize Shipping?

- Reddit Discussions (About Ecommerce Warehouses)

- How WooCommerce Stores Can Benefit from Discount Rules for WooCommerce – Pro?

- Conclusion

- Frequently Asked Questions

What is an Ecommerce Warehouse?

An ecommerce warehouse is a specialized facility where products are stored, managed, and shipped to customers. Unlike traditional warehouses, ecommerce warehouses are designed to handle a high volume of small, individual orders rather than bulk shipments to retailers.

Key functions include:

- Inventory storage: Organizing and storing products for easy access.

- Order fulfillment: Picking, packing, and shipping products accurately.

- Returns management: Processing returned items efficiently.

- Data integration: Connecting inventory with sales platforms to maintain stock accuracy.

By optimizing these operations, ecommerce businesses can minimize delays, reduce errors, and improve customer experience.

Warehouse vs Order Fulfillment Centre: What’s the Difference?

Although people often use the terms interchangeably, a warehouse and an order fulfillment centre serve different purposes in ecommerce operations.

Understanding the difference helps businesses choose the right setup as they scale.

- A warehouse is primarily used for storage. Its main role is to hold inventory safely until it is needed.

- An orderfulfillment is also called a distribution center.

Role of Ecommerce Fulfillment Centres

Ecommerce fulfillment centres are third-party warehouses or in-house facilities that manage the logistics of picking, packing, and shipping orders for online retailers.

These centres are crucial for scaling operations without increasing overhead costs.

The advantages of using ecommerce fulfillment centres include:

- Faster shipping times: Centralized stock allows for quicker delivery.

- Reduced operational costs: Outsourcing logistics reduces labor and storage expenses.

- Inventory management efficiency: Automated systems track stock levels in real time.

- Flexibility for expansion: Easy to scale operations during high-demand seasons.

In essence, fulfillment centres complement ecommerce warehouses by streamlining warehousing and order fulfillment, making the supply chain more reliable.

Key Components of an Ecommerce Fulfillment Warehouse

A high-performing ecommerce fulfillment warehouse is not just a storage space; it’s a strategically designed system.

Here are the core components:

- Receiving Area – Where goods arrive and are checked for quality.

- Inventory Storage – Shelves, bins, and racks organize products for efficient access.

- Picking and Packing Stations – Staff or robots pick items and prepare them for shipment.

- Shipping Area – Orders are labeled, packaged, and handed to couriers.

- Returns Processing – A dedicated space for inspecting and restocking returned items.

- Warehouse Management System (WMS) – Software to monitor inventory, automate processes, and generate reports.

Investing in the right layout and technology ensures smooth operations and reduces errors during online order fulfillment warehouse processes.

Ecommerce Storage and Inventory Management

Effective ecommerce storage is crucial for accurate order fulfillment. Poor storage leads to misplaced items, delays, and dissatisfied customers.

Best practices include:

- Categorization: Organize products by size, popularity, and order frequency.

- FIFO (First In, First Out): Ensures older stock is sold first, preventing obsolescence.

- Automation: Barcode scanning and RFID improve accuracy and speed.

- Real-time inventory tracking: Prevents overselling and stockouts.

With advanced software, warehouses can automatically sync stock levels with online stores, reducing human errors and enhancing ecommerce warehouse solutions.

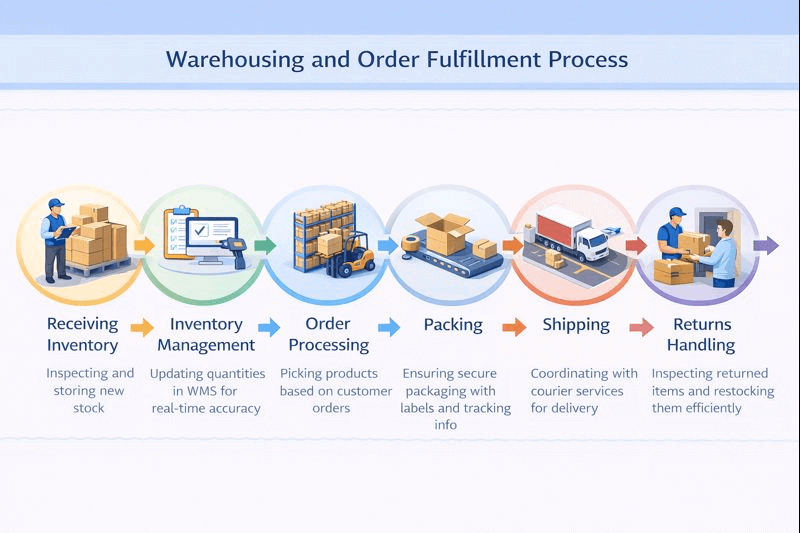

Warehousing and Order Fulfillment Process

Warehousing and order fulfillment form the operational backbone of any successful ecommerce business.

This process ensures that products move smoothly from storage to the customer’s doorstep while maintaining accuracy, speed, and cost control.

When executed properly, it builds trust with customers and supports long-term business growth.

1. The process begins with receiving inventory.

When new stock arrives at the ecommerce warehouse, it is inspected for quantity and quality before being recorded in the system. Accurate receiving prevents future discrepancies and ensures that only sellable products enter inventory. Once verified, items are moved to designated storage locations.

2. Next comes inventory management, where stock levels are updated in the warehouse management system (WMS).

Real-time inventory tracking allows ecommerce businesses to know exactly what is available, across locations if needed. This step is essential for preventing overselling, stockouts, and order delays.

3. Order processing starts when a customer places an order online.

The system generates pick instructions, and warehouse staff or automation retrieves the correct products from storage. Efficient picking methods reduce errors and speed up fulfillment, especially in high-volume ecommerce environments.

4. After picking, items move to packing.

Products are securely packaged, shipping labels are generated, and tracking details are attached. Proper packing protects items during transit and improves the customer unboxing experience.

5. The shipping stage involves coordinating with courier partners to deliver orders on time.

Choosing the right carrier based on cost and delivery speed helps optimize ecommerce warehouse shipping performance.

6. Finally, returns handling closes the loop.

Returned items are inspected, restocked, or processed accordingly, keeping inventory accurate and operations efficient.

Together, these steps create a reliable warehousing and order fulfillment process that supports customer satisfaction while controlling operational costs.

What Role Do Autonomous Mobile Robots Play in Warehouse Picking?

Autonomous mobile robots (AMRs) are changing how an ecommerce warehouse handles picking operations. As order volumes grow and customer expectations shift toward faster delivery, manual picking alone often becomes slow, expensive, and error-prone.

AMRs help solve this challenge by supporting warehouse staff and automating repetitive movement tasks.

In modern ecommerce fulfillment centres, AMRs move independently through warehouse aisles using sensors, cameras, and AI-based navigation.

Instead of workers walking long distances to collect items, robots bring products directly to picking stations. This “goods-to-person” approach significantly reduces picking time and physical strain on staff. As a result, order accuracy improves while productivity increases.

Another major advantage is flexibility. Unlike fixed conveyor systems, AMRs can adapt to layout changes, seasonal demand spikes, and inventory growth.

Ecommerce fulfillment warehouses handling high SKU counts benefit greatly because robots can dynamically adjust routes based on real-time inventory locations. This makes ecommerce warehousing and order fulfillment faster and more scalable.

AMRs also integrate with warehouse management systems (WMS), ensuring real-time inventory updates.

When an item is picked, stock levels are instantly adjusted, preventing overselling and stock mismatches.

For ecommerce businesses aiming to improve order fulfillment speed without expanding warehouse space, AMRs offer a practical solution.

Overall, autonomous mobile robots enhance picking efficiency, reduce operational costs, and help ecommerce warehouse operations meet same-day and next-day delivery expectations.

Related Read: AI in Ecommerce: Complete Guide with Use Cases & Examples

Comparing Picking and Packing Processes Across Fulfillment Centers

Picking and packing are two core activities inside any ecommerce fulfillment centre, but the way they are handled can vary widely depending on scale, technology, and fulfillment strategy.

Understanding these differences helps ecommerce businesses choose the right fulfillment model.

In smaller ecommerce fulfillment warehouses, picking is often manual. Workers receive pick lists, locate items on shelves, and carry them to packing stations.

While this approach works for low-order volumes, it becomes inefficient as the business grows. Larger fulfillment centres use batch picking, zone picking, or wave picking to speed up operations. These methods reduce travel time and improve order accuracy.

Packing processes also differ across fulfillment centers. Basic setups involve manual packaging, label printing, and carrier selection.

Advanced ecommerce warehouse solutions automate packing with dimension scanners, automated label generation, and optimized packaging recommendations. This reduces shipping costs and minimizes damage during transit.

Technology plays a major role in standardization.

Fulfillment centres with integrated WMS and automation can process thousands of orders daily with consistent accuracy. They also support value-added services like branded packaging, inserts, and kitting, which improve customer experience.

Ultimately, advanced picking and packing workflows enable faster ecommerce warehouse shipping, lower error rates, and better scalability.

For growing ecommerce brands, choosing fulfillment centres with optimized picking and packing processes can directly impact delivery speed and customer satisfaction.

How Does Inventory Management Integrate With Order Processing?

Inventory management and order processing are tightly connected in an ecommerce warehouse. When these two systems work together seamlessly, businesses can avoid stockouts, delays, and customer complaints.

Integration ensures every order placed online is fulfilled accurately and on time.

Once a customer places an order, the system immediately checks ecommerce inventory storage levels. If stock is available, the order is approved and sent to the warehouse for picking.

At the same time, inventory quantities are updated in real time to reflect the committed stock. This prevents multiple customers from purchasing the same item when inventory is limited.

In advanced ecommerce fulfillment centres, inventory management systems integrate directly with order management and shipping platforms. This allows automatic routing of orders to the nearest online order fulfillment warehouse, reducing delivery time and shipping costs.

For businesses selling across multiple channels, this integration keeps inventory data synchronized everywhere.

Returns also rely on this integration. When a returned product is inspected and restocked, inventory levels are updated instantly, making the item available for sale again. This closed-loop process improves inventory accuracy and cash flow.

Strong integration between inventory management and order processing is essential for scalable ecommerce warehousing and order fulfillment. It ensures operational efficiency, better customer experience, and reliable growth as order volumes increase.

Types of Ecommerce Fulfillment

Ecommerce businesses can choose from three primary fulfillment models:

- In-House Fulfillment: Business handles warehousing and shipping internally.

- Third-Party Fulfillment (3PL): Outsourcing to fulfillment centres for logistics management.

- Dropshipping: Supplier ships directly to customers without holding inventory.

Each model has advantages depending on the business size, product type, and growth plans. Understanding the right method helps reduce operational costs and ensures timely deliveries.

Ecommerce Shipping and Delivery Operations

Ecommerce shipping and delivery operations manage how orders move from the ecommerce warehouse to the customer. This includes carrier selection, label generation, package tracking, and last-mile delivery.

Efficient shipping workflows reduce delays, lower costs, and improve customer satisfaction. Faster and reliable delivery also increases repeat purchases.

Related Read:Why Customers Are Not Buying in Your eCommerce Store?

What Are the Key Steps in Ecommerce Shipping and Last-Mile Delivery?

Ecommerce shipping begins once an order is packed and ready to leave the ecommerce warehouse. Each step in this process plays a crucial role in ensuring timely and cost-effective delivery to the customer.

The first step is carrier selection. Ecommerce warehouse solutions often compare shipping rates, delivery times, and service reliability to choose the best option automatically.

Next, shipping labels are generated, tracking numbers are assigned, and order details are shared with the carrier system.

After dispatch, the order enters transit, moving through regional distribution hubs before reaching the destination city. This phase is usually predictable and optimized through logistics networks.

The most challenging part is last-mile delivery, which involves transporting the package from the local hub to the customer’s doorstep.

Last-mile delivery is critical because it directly affects customer satisfaction. Delays, failed delivery attempts, or poor communication can lead to negative experiences. To improve this stage, ecommerce warehouse shipping systems use real-time tracking, delivery notifications, and route optimization.

Some ecommerce fulfillment centres also support local fulfillment and micro-warehousing to shorten last-mile distances. These strategies reduce delivery times and costs while meeting same-day or next-day delivery expectations.

Efficient shipping and last-mile delivery strengthen trust, reduce returns, and improve brand reputation in competitive ecommerce markets.

How Technology Improves Ecommerce Warehouse Performance?

Technology improves ecommerce warehouse performance by automating inventory tracking, picking, packing, and shipping processes. Tools like WMS, automation, and analytics reduce errors and speed up order fulfillment. Real-time data helps warehouses scale operations efficiently. This leads to better accuracy, productivity, and overall operational control.

How Do Predictive Analytics Optimize Warehouse Staffing and Inventory?

Predictive analytics is becoming a powerful tool in modern ecommerce warehouses. By analyzing historical data and current trends, predictive systems help businesses make smarter decisions about staffing and inventory planning.

For staffing, predictive analytics forecasts order volumes based on seasonality, promotions, and past sales patterns.

Ecommerce fulfillment centres use this data to schedule the right number of workers at the right time. This reduces labor shortages during peak periods and avoids overstaffing during slow seasons.

Inventory optimization is another major benefit. Predictive models analyze sales velocity, product demand, and replenishment timelines. This helps ecommerce inventory storage systems maintain optimal stock levels. Businesses can restock fast-moving products early while avoiding excess inventory for slow-moving items.

Predictive analytics also improves warehouse layout planning. Frequently ordered items can be positioned closer to packing stations, reducing picking time and improving order processing speed. This directly supports efficient ecommerce warehousing and order fulfillment.

By combining predictive insights with automation and real-time data, ecommerce warehouse operations become proactive rather than reactive. The result is lower operational costs, better customer satisfaction, and smoother scaling as the business grows.

How Ecommerce Warehouse Solutions Optimize Shipping?

Modern ecommerce warehouse solutions leverage technology to optimize shipping, reduce errors, and save costs.

Key optimizations include:

- Route optimization: Software calculates the fastest delivery routes.

- Automated label printing: Speeds up packing and reduces mistakes.

- Inventory syncing: Ensures stock levels are accurate across multiple sales channels.

- Shipping rate comparison: Selects the most cost-effective courier automatically.

By integrating these solutions, online stores can achieve faster delivery, reduce returns, and improve customer satisfaction.

Related Read 7 B2B eCommerce Marketing Mistakes (and How to Fix Them)

Reddit Discussions (About Ecommerce Warehouses)

1. Best Warehouse Management System Recommendations for Growing Ecommerce

Discussion Summary: A store owner seeks a WMS for real-time inventory tracking, multi-location management, and mobile scanning without high costs. Existing solutions like Fishbowl feel outdated, and NetSuite is expensive.

Takeaway: Mid-sized operations need user-friendly, cost-effective WMS solutions. Modern WMS can integrate with ecommerce platforms like WooCommerce, ensuring seamless inventory management and order fulfillment.

2. When to Get a Small Warehouse

Discussion Summary: An entrepreneur anticipates $130k profit in 2026 and needs a small warehouse to scale operations, invest in equipment, hire staff, and reduce CAC while improving delivery times.

Takeaway: Transitioning from home-based operations to a small warehouse requires strategic planning. Even a modest space can significantly increase efficiency, capacity, and revenue potential.

3. Should I Make an E-Commerce Fulfillment Warehouse?

Discussion Summary: A warehouse owner has unused space and wonders if starting an ecommerce fulfillment warehouse is viable. Questions include how to get clients, source products, and compete with Amazon.

Takeaway: Running a fulfillment warehouse can generate steady revenue if structured efficiently. Partnering with online retailers and offering storage, picking, packing, and shipping services is a potential growth model.

How WooCommerce Stores Can Benefit from Discount Rules for WooCommerce – Pro?

For WooCommerce store owners managing their ecommerce warehouse and order fulfillment, integrating sales promotions can further boost revenue.

“Discount Rules for WooCommerce – Pro” allows:

- Creating advanced discount rules for bulk orders or seasonal sales.

- Offering tiered pricing and cart discounts automatically.

- Managing promotions without manual intervention.

- Integrating seamlessly with inventory and fulfillment systems.

This plugin helps store owners optimize sales while maintaining smooth operations in their ecommerce fulfillment centres.

Running a WooCommerce store?Simplify order-based promotions with Discount Rules for WooCommerce – Pro while your warehouse handles fulfillment smoothly.

Conclusion

An ecommerce warehouse is the backbone of successful online businesses.

By optimizing storage, inventory management, and order fulfillment, businesses can reduce costs, improve delivery times, and enhance customer satisfaction. Integrating modern ecommerce warehouse solutions ensures accurate stock tracking and efficient shipping.

For WooCommerce store owners, combining a well-managed warehouse system with Discount Rules for WooCommerce – Pro allows seamless promotions, higher sales, and a competitive edge.

Investing in both logistics and smart discounting is the key to scaling an ecommerce business globally.

Also Read

1. 10 Types of eCommerce Marketing Your Online Store Should Follow

2. Everything You Need to Know About Driving Conversions on Your eCommerce Website

3. WooCommerce Free Shipping: A Complete Guide With Examples

Frequently Asked Questions

Start with market research, secure a warehouse, invest in WMS (Warehouse Management System), and establish partnerships with retailers or suppliers.

You should seriously consider a WMS if:

1. You’re handling growing order volumes, and manual tracking is slowing you down.

2. Inventory is stored across multiple locations or zones.

3. Picking and packing errors are increasing.

4. You need real-time inventory visibility.

Fulfillment speed is starting to impact customer satisfaction.

Skills include inventory management, logistics, marketing, customer service, and tech-savviness for software tools.

It refers to the process of receiving, processing, and delivering orders to customers.

In-house fulfillment, third-party fulfillment (3PL), and dropshipping.

Amazon warehouses primarily store inventory, while fulfillment centers handle picking, packing, and shipping for sellers.

Dropshipping is an ecommerce fulfillment model where the seller does not store products in their own warehouse. Instead, when a customer places an order, the seller forwards the order to a third-party supplier, and that supplier ships the product directly to the customer.

How Dropshipping Works?

1. You list products on your online store

2. A customer places an order

3. The order is sent to the supplier

4. The supplier picks, packs, and ships the product

5. You earn the margin without handling inventory.

Even though dropshippers don’t own warehouses, warehouses are still involved; they’re just owned by suppliers or fulfillment partners. The supplier’s warehouse functions as the ecommerce fulfillment warehouse, handling:

1. Inventory storage

2. Order picking and packing

3. Shipping and returns.

In essence, dropshipping outsources warehousing and order fulfillment entirely.